Oxygen Lance and Its Servo System

Descriptions:

With our independent R & D, design and manufacture, we have reached nearly a hundred specifications of product series for oxygen lance, lance hose, oxygen lance nozzle, servo system, furnace tuyere, slag notch, electrode chuck for electric furnace, copper water tank and other water-cooled copper casting products which formed a unique series of Jully Science & Technology and stands in a leading position in the aspects of technique, process, quality and testing equipments.

With our independent R & D, design and manufacture, we have reached nearly a hundred specifications of product series for oxygen lance, lance hose, oxygen lance nozzle, servo system, furnace tuyere, slag notch, electrode chuck for electric furnace, copper water tank and other water-cooled copper casting products which formed a unique series of Jully Science & Technology and stands in a leading position in the aspects of technique, process, quality and testing equipments.

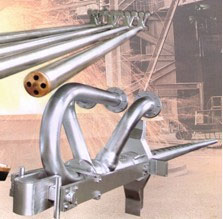

1. Cluster Lance

Our Dual-fired & single flow path cluster lance is a new oxygen blowing technology developed in recent years. It utilizes pneumatics by adding an adjoint flow system to form an oxygen jet flow similar to the laser beam and greatly slow down the decaying speed of oxygen jet flow. The jetting distance of cluster jet lance is much far away to the liquid steel surface than that of traditional supersonic oxygen lance. The penetration depth to the liquid steel pool is 80% deeper than that of traditional jet method, but moreover, the sputtering is greatly reduced.

According to the special service environment of oxygen lance, we change the oxygen lance nozzle into a cone shape (referred as little cone nozzle) to get the features of: firstly, it reduces the possibility of adhering slag; secondly, since the nozzle’s diameter becomes smaller than the lance, the flow speed has been changed so as to increase the cooling effectiveness and extend lance’s service life. Meanwhile, we lengthen the nozzle’s height from 30mm to 70mm to reduce the liquid steel flushing against the welding seam between steel and copper.

Features of New Type Oxygen Lance:

1. With multi functions of oxygen blowing, combustion, secondary combustion and centralized autocontrol to reduce facility costs of separate setting and process cost of separate operating for each system.

2. With the function setting of combustion, the melting scrape can be pre-heated so as to reduce power consumption (at least 20 KW.h/ton).

3. With better impacting and stirring abilities, the utilization rate of oxygen and powdered carbon been increased, therefore, the consumption of oxygen and powered carbon reduced.

4. With the secondary combustion function, fully utilizing the CO combustion inside the furnace to increase the furnace temperature in order to decrease energy consumption.

5. Due to the sputtering reduced, the iron content in the slag been reduced, therefore, the metal yield increased but the maintenance cost for furnace body been reduced.

6. Lance blowing position being lifted higher, but the jet stream keeps the same impacting depth to the liquid steel, in a result that the service life of lance nozzle been increased.

Based on the above, the oxygen lance developed and invented by us has the features of no sputtering, less adhering slag, quick decarburizing, pool evenly heated up and cinder re-dry avoided etc. Meanwhile, a steady flow section is added at the nozzle outlet to make the blowing more stable. The nozzles are made of chrome, copper and other microelements which have the advantages of high softening temperature, nice heat conduction, wear-resisting, anti-detonation and high crack hardness, with effects that the pure copper can’t realize. We adopted many advanced techniques in production and process to make the nozzle’s service life 50% longer than other similar products, for example, adopting automatic welding technology to avoid cracking at the welding seam between copper and steel.

Oxygen Lance Series Product

Appling Site